Others may already stop at sustainability. Ass Altenburger is only just getting going.

They make optimum use of the loading areas of the transport vehicles to generate fewer CO2 emissions.

Your logistics department works with a planning tool that can optimally calculate and utilize the loading area of the transport vehicles. This means that journeys with half-empty vans or trucks can be avoided.

They mainly use electric forklift trucks and thus reduce overall emissions.

When purchasing new transport vehicles for production, the company has always made sure that electrically powered vehicles are used.

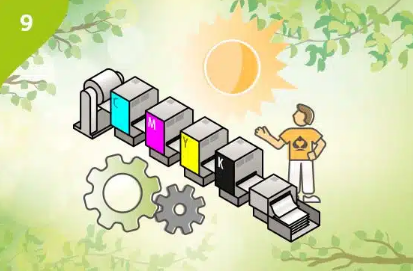

They work with so-called “process-free” printing plates. These do not require any chemicals for development.

The printing plates they use do not require any chemicals at all – resulting in a beautiful and environmentally friendly print.

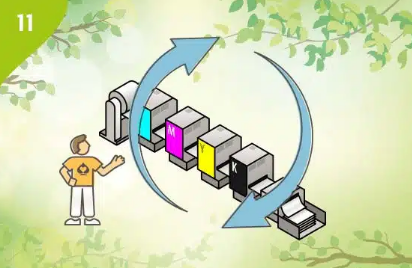

They reuse the print sheets used to set up the machines several times and sort them for proper disposal.

When setting up the printing press, care must be taken to ensure that the image is printed correctly on the sheet. They use printed sheets on both sides, i.e. twice, in order to produce less hazardous waste.

They work continuously to make optimum use of their printed sheets and thus avoid unnecessary waste.

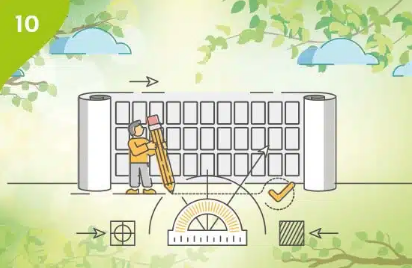

Their planning department and technical product development work daily to utilize every last millimetre of the sheets to minimize waste and unused material. Thanks to many years of experience and the necessary know-how, they place as many cards as possible on one sheet, for example.

They use tension belts for the internal transportation of their components in order to save on stretch film. This reduced consumption by around 20% in 2020.

Your environmental team has identified alternatives for in-house transportation to save on plastic film. For example, tension belts are used or components are stowed in cardboard boxes that can be used again and again to promote the concept of sustainability.

ASS Altenburger have said that they focus a lot on sustainability! But at least it’s about environmental protection. They are not stingy.

They use reusable cleaning cloths in their production and have them cleaned after use.

They also avoid using disposable materials when cleaning machines or surfaces. They use reusable cleaning cloths that are washed industrially and in an environmentally friendly way and are then ready for use again.

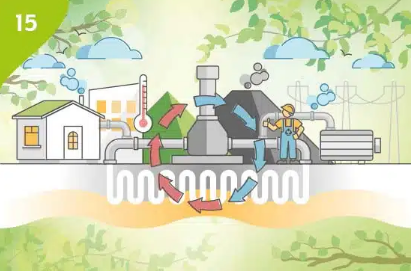

We operate a modern heating system that works 20% more efficiently and therefore produces less exhaust air.

Our heating system was adapted to the latest standard last year and works with new technology.

We reuse cards that have been produced in excess and make them available to laboratories as kiloware. Laboratories use them in their daily work, for example to sort tablets.

Playing cards that are produced in excess are not thrown away immediately, but made available to laboratories, for example. On the one hand, this means we have less waste, and on the other, it offers medical facilities inexpensive and sustainable aids for their work.

They use the exhaust air from the heating system to recover heat and thus produce hot water.

The exhaust air produced by heating is not discharged outside unused. Instead, they use it to produce hot water for the sanitary facilities.

They use the ventilation system in the print shop for heat recovery, i.e. the exhaust air from the printing press is used to heat the room.

The heat generated by the printing press is used to heat the room. This saves you heating costs and protects the environment because we do not discharge the warm air to the outside.

They use “green” electricity throughout the company.

They receive sustainable electricity from their electricity provider, for example from wind turbines or solar plants.

They have equipped 90% of their office lighting with LED technology and are saving electricity as a result.

The lighting throughout the company is gradually being converted to more resource-efficient LED technology.

They pay attention to their power consumption and switch off power strips when they leave the workplace, for example.

They raise awareness of sustainability among their employees by focusing on small, simple changes. For example, all employees switch off unused devices when they leave the workplace.

For the future, they are planning

ASS Altenburger has long attached great importance to sustainable products and environmental protection. They carry out every step of their work with an awareness of their responsibility towards nature and future generations. But even though they are trying very hard, they are far from satisfied. They are constantly reviewing their processes for possible improvements and have also set themselves ambitious goals for the future. The overriding aim is to further reduce plastic.

Find out exciting news and more about our products every week at varia.org/blog !